The main goal of the project is to develop a test rig able to test fuselage curved panels. In this project Applus will take advantage of its 12×12 meters metallic strong floor to implement highly adaptable test rig to test curved stiffened panels of different size, geometries and material type.

The development of this test rig is central on this project. We will need to make sure that we are designing, preparing and building an optimized test rig suitable for the testing goals, mainly the realization of an efficient, reliable and cost-effective test bench suitable for the full-scale testing of curved aeronautical stiffened panels. To achieve this, the development of the test rig will take into consideration both the development of a virtual testing methodology and advanced simulation methodologies, and as well the further development of an innovative, cost-efficient, easily adaptable fuselage panel full-scale test bench.

This test set up will be able to test fuselage curved panels in conditions of structural and internal pressure fatigue, applying forces of tension, compression, shear and combinations of them. One of the main characteristics of the developed test rig is that it will be easily adaptable to different kind of tests.

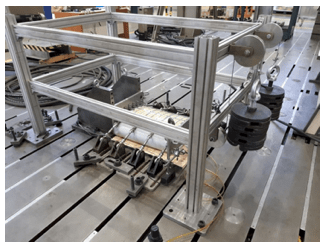

Prior to building the test rig, and based on the test rig simulations performed in order to identify the essential rig characteristics, Applus has built a mock – up (shown in the photo below) in order to prove that the concept idea works as expected.